In the bustling pipelines of industry, the Electromagnetic Flowmeter stands as an unassuming observer, quietly translating the language of flowing liquids into signals we can understand. Born from Michael Faraday’s law of induction, this device listens not with ears but with electrodes, sensing the subtle electrical whispers generated when conductive fluids journey through magnetic fields. Its elegant simplicity—no moving parts to wear down, no obstructions to hinder flow—makes it a guardian of accuracy in water treatment plants, chemical reactors, and even the human bloodstream. Unlike mechanical meters that interrupt the flow’s dance, the electromagnetic variant observes without touching, a silent partner in measurement.

The Whispering Field: How Electromagnetic Flowmeters Sense

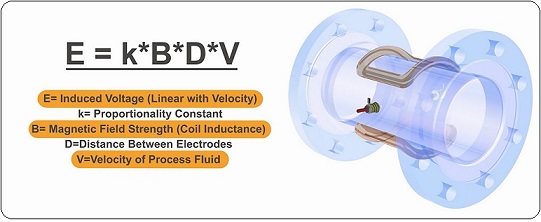

At its heart, the Electromagnetic Flowmeter conducts an invisible symphony. When fluid—be it water, acid, or slurry—flows through its metering tube, the meter’s coils generate a magnetic field perpendicular to the flow direction. This field acts like an ethereal harp, and as conductive fluid strings “pluck” through it, tiny voltages awaken at the electrodes. Faraday’s law tells us this voltage (E) emerges as a linear child of average fluid velocity (*v*), magnetic strength (B), and pipe diameter (D): E = k·B·v·D.

Early designs wrestled with noise. Stray electrical interference or uneven flow profiles could distort signals, like static drowning out a faint melody. To combat this, engineers embraced alternating magnetic fields—first sine waves, later low-frequency square waves—to distinguish true flow signals from background chaos. Square-wave excitation, notably, minimized polarization at the electrodes and allowed synchronous detection, effectively silencing drift and hum. Yet, turbulence remained a tricky adversary. In asymmetric flows, traditional Electrode setups struggled as voltage patterns skewed, introducing errors that demanded long inlet pipes to “calm” the stream before measurement.

The sensor’s physical form evolved too. Cylindrical probes once cast disruptive wakes, their wake vortices muddying signals. Then came the elliptical water-drop shape—a streamlined contour that hugged flow lines gently, reducing turbulence and amplifying signal clarity by over 15% in simulations. Meanwhile, non-contact capacitive electrodes emerged for aggressive fluids. By isolating electrodes behind liners, they resisted corrosion from acids or slurries that would erode conventional units, though they demanded more sensitive electronics to detect fainter signals.

Evolution’s Current: Innovations in Electromagnetic Sensing

Modern Electromagnetic Flowmeters blend refined hardware with intelligent processing. To combat noise, multi-stage signal chains now prevail: a micro-volt signal first amplified differentially, then filtered through tunable bandpass stages, before CPLD-driven rectifiers eliminate switching artifacts. Such designs achieving 0.1% precision across 0.1–15 m/s, even amidst factory-floor electrical clamor.

Magnetic field uniformity, once a persistent hurdle, saw breakthroughs with Helmholtz coils and finite-element optimization. By sculpting fields into near-perfect homogeneity using COMSOL simulations, engineers ensured each fluid molecule contributed equally to the signal, regardless of its path through the pipe. New mesh electrodes further revolutionized resilience. Their grid structure averaged readings across multiple points, diminishing errors from localized eddies. In tests, they slashed low-flow inaccuracies by 7.5% and shrugged off electromagnetic interference 5% more effectively than standard electrodes.

Perhaps the cleverest leap is empty-pipe detection. Older meters faltered if fluid ebbed below the Electrode, misreporting flow or alarming falsely. Now, CPLDs scrutinize waveform shapes—comparing excitation patterns to electrode responses—to discern air from liquid without relying on error-prone conductivity checks. This intelligence prevents costly miscalculations in batch processes or leak detection systems.

Looking ahead, miniaturization and wireless connectivity beckon. Tiny implantable electromagnetic sensors already track blood velocity in arteries as narrow as 1mm, their coils humming softly beneath the skin. Meanwhile, industrial giants stream data via IIoT networks, their algorithms predicting maintenance from signal drift. Yet, the core promise remains unchanged: to listen, faithfully, to the stories flowing within. As long as liquids course through pipes—whether carrying life, chemicals, or energy—the Electromagnetic Flowmeter will translate their motion into meaning, one silent volt at a time. Their affect on process control and resource management is profound, and industry remains heavely reliant on their unblinking gaze.